Bio-Chemicals

Bio-Propylene

Conversion of ethanol to ethylene is an old, well-established process – but is not used widely used for two reasons. The reaction is equilibrium limited and highly endothermic. Large amounts of heat input are required to maintain adequate reaction rates. This leads to a complicated reactor and furnace designs which in turn translates to high capital costs for the ethanol to ethylene plant. Converting ethanol to propylene and butene eliminates many of these problems. The ExTol process is designed to produce bio-propylene in high yields from ethanol using conventional FCC reactors

Bio-Naptha

Bio-naphtha is the missing link between biomass and petrochemicals and refining facilities, as it can be economically produced in small, distributed facilities and then easily and economically transported to central large-scale processing facilities. Exelus uses a unqiue low temperature hydrolysis process to first convert lignocellusicbiomass to oligosaccharides which are then hydrogenated directly to light naphtha. No mineral acids are used in this process

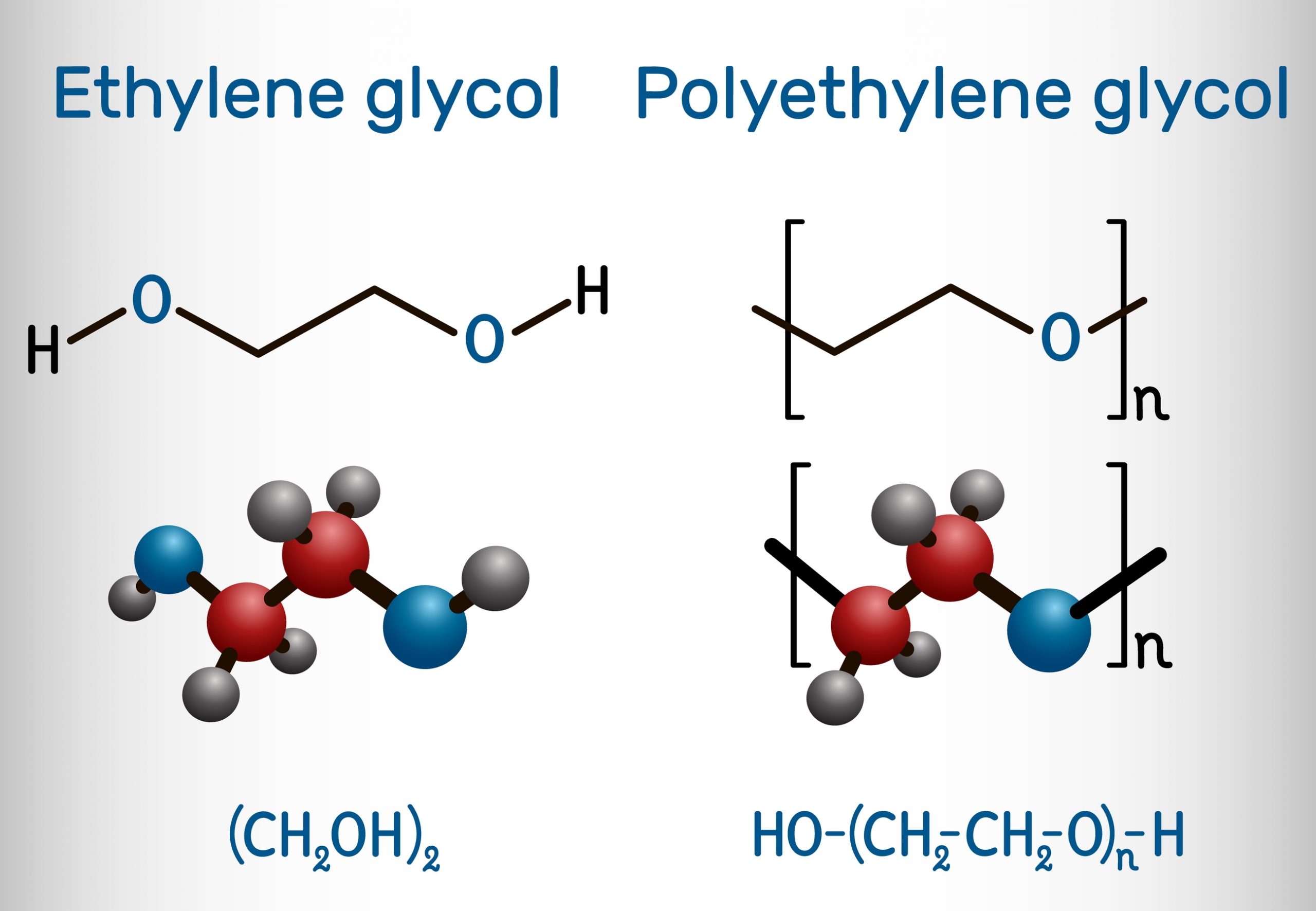

Bio-Glycols

Ethylene glycol (EG) and propylene glycol (PG) serve as the chemical feedstock for making polyester fibers, PET melt and are used as antifreeze. The transformation of lignocelllosic biomass to Ethylene and Propylene Glycol is similar to the Bio-Naphtha process, but with a different catalyst. The chemical pathway avoids the formation of highly reactive intermediates to overcome the selectivity issues that plague other chemical routes